Visitors’ centre at ecological regeneration project beside the River Lea will be complete for April 12 event as the weather warms

Subscribe to our free Wharf Whispers newsletter here

April 12, 2025, is set to be a momentous day at Cody Dock.

From 1pm-7pm, the east London ecological regeneration project will host its Spring Forward event – but things are going to be a bit different this year.

While the rolling bridge will be ceremonially upended, plants will be sold, workshops hosted and performances staged, there’s a wider triumph to celebrate.

Specifically, the Cody Dock visitors’ centre will be unveiled in its finished form.

Now named The Barn, the team has been working hard to install windows, doors, walls and ceilings, as well as raising the land outside the structure, ready for the event.

For those attending, it will be the first opportunity to explore the finished space – an amenity which will serve as the focus for the site, a public lodestone for those passing through.

getting ready for the launch

“It’s a wonderful event, celebrating the arrival of spring and the world shaking itself back to life with a real focus on ecology,” said Bella Quirin, heritage programme manager at Cody Dock.

“Spring Forward is all about helping people to reconnect with nature after the colder weather.

“Among the highlights will be Tails Of Migration, a really interesting workshop run by our education team.

“Lots of species return to the UK from warmer habitats at this time and it’s all about showcasing those journeys and getting people to interact with them.

“The idea is that participants will also think about their own journeys and the places they have lived before, whether those are across large distances or relatively small ones.

“From that, we’ll be able to capture people’s oral histories as part of our ongoing heritage work.”

The Cody Dock scheme is complex in its scope and events such as Spring Forward offer visitors an opportunity to get to grips with some of the many projects under its umbrella.

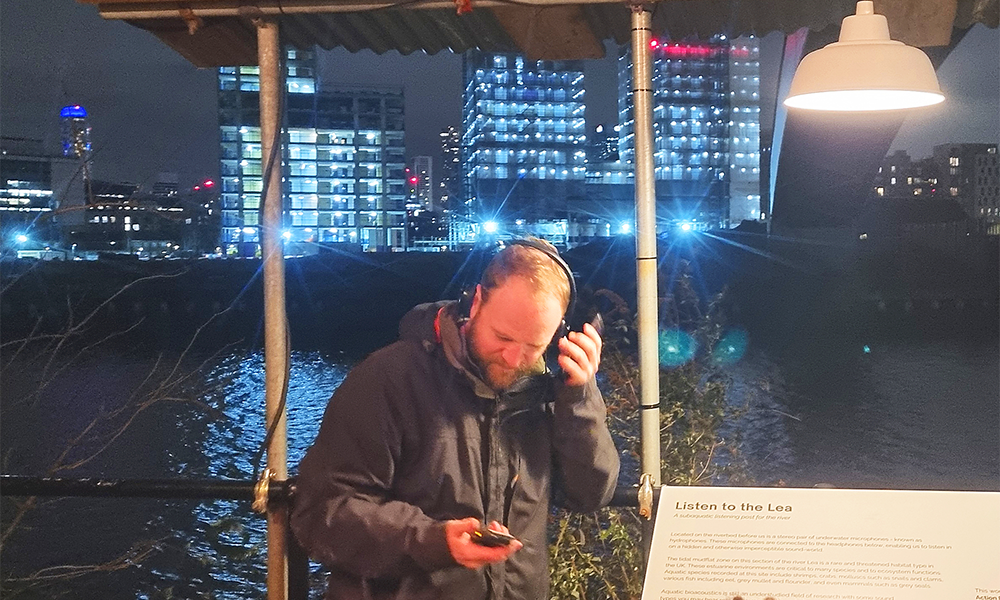

There’s its role as a place of work and study, with artists resident in its studios and collaborations with academics to study and respond to the local area a regular feature of its operations.

Then there’s its commitment to supporting and studying local wildlife as well as stewardship of the tidal Lea.

It’s a place for innovation and experimentation as much as conservation.

Local history is another major thread running through its fabric with Spring Forward visitors able to view progress on work to restore the Frederick Kitchen, probably the last boat to be built by the Thames Ironworks at the mouth of the Lea.

This craft will eventually be used as the roof of a heritage pavilion, which will host a succession of exhibitions about the history of the local area.

connecting to history at Cody Dock

“That’s set to open next spring and it will be a fantastic space,” said Bella.

“It will have glass walls, so visitors will be instantly connected to the water, even when they’re inside.”

The April event will also include a chance to view Cabinet Of Curiosity No. 1, the first of three artist commissions exploring local history.

The work focuses on the Thames Ironworks and includes verse from William McGonagall recalling the calamitous launch of the battleship Albion that saw more than 30 people lose their lives when a stage collapsed into the water.

It’s just one of the many ways that Cody Dock is seeking to nurture connections between past and present as its regeneration of the 2.5 acre site continues.

“One of the things about Cody Dock – especially The Barn – is that we really want people to feel there’s collective ownership of our spaces as well as them being an attraction,” said Bella.

“The visitors’ centre will be such a dynamic space.

“It will work for our school visits, our ecology team if they’re hosting workshops, but also as a place for performances.

“There will be a full lighting system and we feel that there’s already a really strong vision emerging for it. It will act as a beacon for the whole project – somewhere people can come together.”

While the building itself has been used at previous events, hosting musical performances, dances and a sonic excursion along the Lea with visitors’ feet immersed in sand, the addition of sealed windows and doors will allow for greater flexibility.

There are plans for regular film screenings, with directors invited to participate in Q&A sessions, although full details have yet to be revealed.

seeking a food and drink partner

Another major change will be the completion of The Barn’s kitchen, which will provide cafe and dining facilities for the site.

Cody Dock is currently inviting applications for a partner to run this part of its operation.

The aim is to both generate income for the project and Gasworks Dock Partnership – the charity overseeing it – and to draw more visitors to the site.

GDP is hoping to attract a partner that aligns with its charitable aims, prioritising recruitment of local staff, paying the London Living Wage and using ethically sourced ingredients.

“The cafe will very much be central to our operation in many ways,” said Simon Myers, CEO of GDP.

“They will be most likely to come into contact with people passing through, so it’s really important that their aspirations and aims chime with our objectives.

“We’re about place-making and greater community cohesion so we need to be somewhere that’s really welcoming to everyone.

“We’re also an environmental organisation, so produce that’s served here needs to be sustainably sourced and, hopefully, the food and drink on offer will also reflect the diversity found in the local population.”

key details: Spring Forward at Cody Dock

Spring Forward is set to take place at Cody Dock on April 12, 2025, from 1pm-7pm. The event is free to attend, spots can be reserved digitally.

Cody Dock is easily reached on foot from Star Lane DLR station via Cody Road and South Crescent.

You can find out more about the many projects and initiatives based there online.

Find out more about Spring Forward here

Read more: How Green Pioneer could be the future of decarbonised shipping